This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

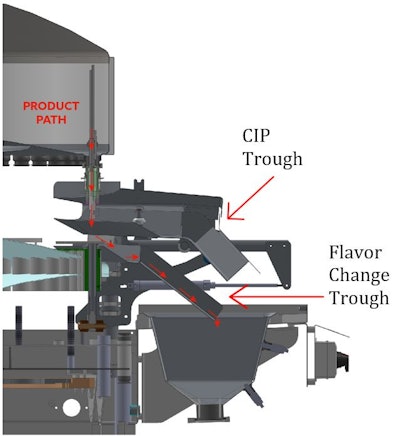

Fogg’s trough is a time saver when changing flavors. Because the CIP trough isn’t being used, so there is no need to wait for the bowl and the trough to move out of the way of each other. This saves multiple minutes in the process each time a change is done. The trough sits right beneath the CIP trough so that product can be purged from the bowl and collected in the same spot without having to purge the product on to the base.

This is especially helpful in the case of hot-fill applications. When time saving is essential, and you do not have the flavor change trough, most customers will purge on to the base. With hot-fill applications, the hot product can warp the base doing long term damage. This eliminates that possibility. This feature is controlled by the touch of a button.