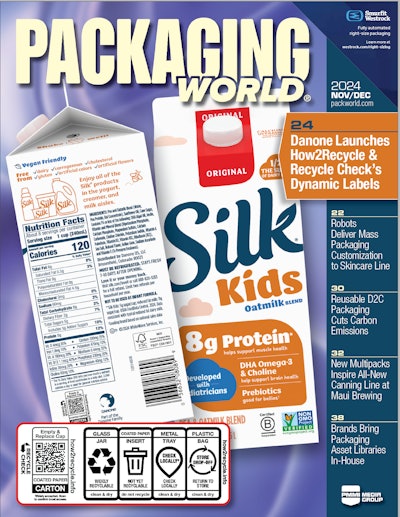

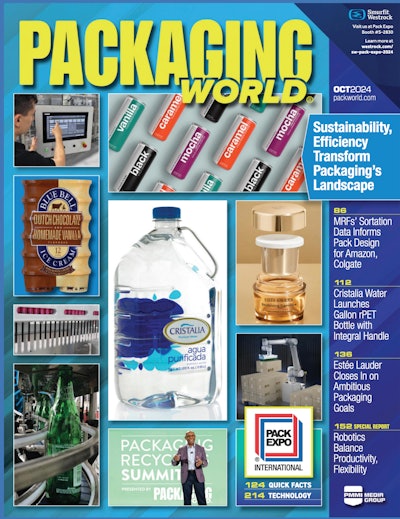

Sourced locally from natural springs in Puerto Rico’s Caguas Valley, East Valley, and North Aquifer, Cristalia Premium Water says it bottles and sells the purest water on the island. The brand’s popularity there certainly substantiates the claim. Owned by vertically integrated Dominican Republic brand owner Diesco Industries and bottled by Diesco’s Pac Tech International (PTI) operation in Las Piedras, PR, Cristalia has long been the market leader in its corner of the Caribbean.

Even so, the brand recently had faced headwinds from near-identically packaged challengers in the 1-G HDPE jug format. Consumers couldn’t differentiate jugs of Cristalia from competitors sitting right alongside it on the retail shelf. This caused sales to plateau without much space for growth in a constrained geographical region. Outside of a race to the bottom on price, there weren’t a lot of levers to pull to help Cristalia to distinguish itself on a crowded shelf of similar-looking gallon jugs.

For stateside city dwellers, it’s worth noting that this 1-G format is particularly popular in Puerto Rico. Consumers there buy a lot of bottled water in larger pack formats than we might see on the mainland. Recent natural disasters like hurricanes Irma and Maria underscore the importance of having potable water, and lots of it, available on a Caribbean island. Tap water is perfectly safe everywhere in Puerto Rico, but hurricanes can disrupt its supply, and storm memories are pervasive in the area.

Such was the state of affairs in the Puerto Rican water market about five years ago. To reinvigorate brands like Cristalia, and explicitly commit itself to supplying the storm-prone region, in 2019 Diesco chose to significantly boost and reinvest in its PTI bottling operations. It converted a large brownfield, former candy manufacturing plant into a state-of-the-art water bottling facility, upping its size, throughput, and capability. A big driver for the new facility was the shadow of then-recent Hurricane Maria—Grupo Diesco CEO and President Manuel Diez Cabral saw that Puerto Rico didn’t need to go through another water shortage-related humanitarian disaster. Import substitution strategies wouldn’t cut it in an emergency. The PET lightweighting trend was well underway anyhow, and investment was already necessary to modernize facilities and capabilities on the single-serve lines. This facilities investment coincided with Cristalia looking to differentiate its 1-G water line.

New bottle on the block

Meanwhile, a fledgling PET bottle technology using a preform with an integral handle was emerging in the States. Packaging World covered early iterations of the tech at PACK EXPO International in 2018. The rights to the technology changed hands a few times, and owners reached out to InterTech, an engineering, procurement, and construction firm in Atlanta, to help develop it and work with OEMs to develop machinery to support the technology. The decision was made to create a new company, Handle Preforms, LLC, and to go to market under the catchier BottleOne moniker.

This proprietary, license-based PET preform technology and stretch blow molding format includes an integral handle on the preform that remains firmly affixed to a sturdy, injection molded neck before and after the bottle is blown. Unlike opaque HDPE jugs, BottleOne PET bottles are transparent, so proponents say they offer greater consumer impact on the shelf—something that might pique the interest of a Cristalia brand seeking differentiation. Just like the HDPE jugs BottleOne seeks to disrupt, the integral handle also allows for easy one-handed pouring. This is important since these aren’t single-serve formats.

The bottle and PET material is also more robust and rigid than the standard 1-G HDPE jug format, behaving more like a 2-L carbonated soft drink (CSD) bottle than a milk jug, stakeholders say. Its sturdiness and hermetic seal let consumers store it horizontally in a home refrigerator without fear of leakage. That’s not a strong suit of HDPE jugs, as anyone who has made that mistake with a milk jug knows. For Caribbean island consumers who may seek to stock up, vertical stacking without fear of collapse and resulting leakers is another benefit—one that extends upstream into the supply chain. Retailers can simply stack bottles as a display without a shelf, and distributors can stack pallets of bottles in transportation using only shrink wrap. That means bottlers like PTI could forgo reliance on corrugated tray and case materials, using only shrink film in its place. Specific to high-humidity tropical environments like Puerto Rico, where corrugated breaks down quickly, this is especially advantageous. The BottleOne format’s top-load strength allows for stacking in retail settings. Multipacks of 2 by 3 use decorated, registered shrink film instead of corrugated for improved branding.

The BottleOne format’s top-load strength allows for stacking in retail settings. Multipacks of 2 by 3 use decorated, registered shrink film instead of corrugated for improved branding.

It bears mentioning that BottleOne isn’t the only water bottle game in town, even in Puerto Rico. PepsiCo and Coca-Cola, for instance, have their own water brands in 1-G PET bottles in the market. But BottleOne’s integral handle distinguishes it. Other brands use a bale- or pinch-grip accessory handle that’s mechanically affixed to the neck ring but is not contiguous with the bottle. BottleOne says retailers have trouble with the bale-grip format since the handles are prone to falling off in the supply chain, thus are harder to stock when they arrive at loading docks. BottleOne stakeholders say that consumers find these bale-grip rings can be uncomfortable to carry. Additionally, these types of handles do not allow for a single hand pour.

Burning the ships to make the switch

As Diesco moved into the new facility, bottler PTI’s existing packaging line equipment also began to move. That included several high-speed, single-serve PET bottled water lines. There were tentative plans to move the water 1-G HDPE water jug line over as well. Notably, the brand had not been blowing its HDPE jugs on-site. It had been blowing the bottles off-site at one of Diesco’s plastics facilities, or sometimes taking delivery from a third party. This was a suboptimal solution for both efficiency and sustainability, as transporting empty 1-G bottles is said to be “shipping air.”

But that wouldn’t be a problem much longer. By the time of the facility migration, Diez and his team had caught wind of the BottleOne format.

Multiple varieties of Cristalia water on a retail shelf. While a gallon is equivalent to 128 oz, 120-oz jugs (near gallon equivalent) are the standard in Puerto Rico.

Multiple varieties of Cristalia water on a retail shelf. While a gallon is equivalent to 128 oz, 120-oz jugs (near gallon equivalent) are the standard in Puerto Rico.

But there’s also the issue of leaking with a polyethylene gallon since the neck is not perfect—Diez says this factor is reported as an issue in all the industries that use it, like dairy and edible oil because it’s not an injected neck like on the PET.

“We could eliminate all the leakers that are inherent with the package. And the neck of the PET bottle is just superior closure-wise, the top-load strength is much better, and you can avoid bottles being crushed,” Diez says. “And environmentally, it made all the sense in the world. We’re going to eliminate the corrugated, which is a huge cost and it’s simply a transport vehicle. We also can switch the resin so that we convert to food grade recycled PET [rPET]. One of the things we are doing, and we are actually going to inaugurate it later this year, is the first rPET plant in the Caribbean. By the end of this year we’re going to have recycled content, and a closed loop system where we can actually grab the discarded bottles, convert them to food grade rPET, and insert them into the finished product. We could reduce dramatically our carbon footprint.” Preforms first travel into a five-cavity SIPA linear SFL blow mold machine, where they’re blown at a rate of 83 bottles/min.

Preforms first travel into a five-cavity SIPA linear SFL blow mold machine, where they’re blown at a rate of 83 bottles/min.

Once the decision was made to adopt BottleOne, there was no looking back for Diesco, PTI, or its Cristalia brand. Diez recalls a regionally significant story about the Spanish conquistadors burning their ships once they arrived at a destination to show their commitment to staying, and not be tempted to return to their departure port.

“So that’s what we did. We literally mothballed the polyethylene lines, put them on a couple 40-ft. container trucks, and said, ‘We’re committing to this, there’s no going back.’”

Challenges in implementation

“We didn’t have many concerns in terms of consumer acceptance,” Diez says. “We had done all the homework we needed and felt comfortable with that. The biggest concern was operational. Our challenge was to ramp up efficiently, so that the cost savings that we were getting in other areas weren’t consumed by operational inefficiencies.”

Indeed, Cristalia’s BottleOne adoption was a trial by fire for the format, which had never run 24/7 before. To account for the unforeseen, Diez and PTI overshot their production capacity, knowing they might not get the efficiency levels they were accustomed to.

“We knew that the ramp up curve was going to be slower than what it usually is when you set up a normal PET machine and filling line. By oversizing production, we felt we were covered in terms of supplying the market,” Diez says. Blown bottles exit the blow molder on Dyco conveyers.

Blown bottles exit the blow molder on Dyco conveyers.

He saw other operations start up their new PET bottling lines haltingly, ramping up in dribs and drabs. Diesco and PTI used a different approach with the Cristalia 120-oz PET bottle line.

“We have 60 years of experience operating machinery and equipment. We know that unless you start working it 24 hours a day, seven days a week, you’re not going to know how to really polish it and make it run as efficiently as possible. We had done enough testing and on-site visits to manufacturing facilities that were used as test sites. We had done our due diligence with BottleOne. We burned our ships and jumped in right to full production, and then it was a matter of fine tuning at that point.”

The packaging line

Packaging World usually begins its beverage filling line reporting at a bottle unscrambler or a depalletizer. But with a vertically integrated company like Diesco, we can reach a bit deeper into the supply chain to better understand how the whole system flows. It also doesn’t hurt that a key partner in the BottleOne format is InterTech, the OEM agnostic integrator that helped to select and procure equipment for Cristalia’s 120-oz PET bottle operations at PTI.  Bottles are filled on an eight-head monoblock filler from Fogg Filler, with capping (center right) immediately following.

Bottles are filled on an eight-head monoblock filler from Fogg Filler, with capping (center right) immediately following.

“In our partnership with BottleOne, we are making the preforms locally in our plant in Dominican Republic, and we ship the preforms to PTI in Puerto Rico to be blown and filled. We do that for all our PET preforms, not just the gallon PET. But the integral handle on the BottleOne format is certainly unique among our preforms,” Diez says, without revealing the secret sauce science behind the integral handle. “There’s a whole concept behind this system in terms of energy costs being less [in DR], economies of scale, flexibility, and the ease of getting product from one island to the other because there’s a lot of commerce between them. You can put a container in Puerto Rico in less than 24 hours,” Diez explains. “It makes a lot of sense for us to do it that way.”

Plus, shipping preforms is a lot more efficient and sustainable than shipping blown bottles, even over shorter distances like from the Dominican Republic to Puerto Rico.

Diesco’s plastic subsidiary Polyplas Dominicana uses injection molding equipment from Husky with the proprietary integral handle mold, thus achieving the robust injection molded neck and handle in the preform. Those are bulk shipped to PTI, where bottles are stretch blown in-line prior to filling. Stretch blow-molding happens using a five-cavity SIPA linear SFL blow mold machine, which feeds empty bottles into accumulation and buffer conveyance from Dyco.

“The buffer gives the filling line enough space to keep filling if we’re doing tests on the preform molds or anything else,” Diez says. “The empty bottle is heavy enough and stable enough that it can travel on a regular conveyor line down to the to the filling station.”

Prior to filling, bottles pass through an MCC labeler that affixes adhesive applied labels from rollstock supplied by local Puerto Rican film converter CCL. In designing the labels, the Cristalia team got creative with one of PET’s competitive advantages over HDPE: transparency. Two mostly transparent labels are applied to each bottle—one on the front, one on the back. The Cristalia logo is prominently positioned on the front label above text indicating which of the five varieties of water it contains. Color is used sparingly on these labels, leaning into the transparent aesthetic of water, but each of the five SKUs is associated with a color. For instance, purified water for babies is yellow, and distilled water is red. These colors appear on the labels in aqueous patterns, like beaded water droplets or dye entering a solution. These aqueous patterns also appear on the back label. Though the pattern is mostly the same as the label on the front, the cylindrical curvature of the bottle creates a lens or fish-eye effect that magnifies the colored beads of water that appear on the back label. Using transparency and magnification, a simple design cleverly achieves an outsized shelf impact. Caps are color-matched to the SKUs that they close, making it easy for consumers to identify their preferred variety, whether distilled or alkaline, on the shelf. Cristalia is the only bottler in the region that manufactures purified, distilled, alkaline, and baby water. Multipacking in a Robopac shrink tunnel; no corrugated is needed.

Multipacking in a Robopac shrink tunnel; no corrugated is needed.

An eight-head monoblock filler from Fogg Filler, a ProMach brand, is next. Color-coordinated caps are torqued on immediately after filling. As they exit the monoblock, filled and capped bottles receive an inkjet date code. “Because of our FSS22000 certifications, we have full traceability of all the products that we make,” Diez says of date coding operations. “Once they’re packed, we can trace everything everywhere.”

Speaking of caps, Diesco’s Polyplas Dominicana injection molds those, too. Instead of an all-PET cap and closure design, Diez and PTI opted to keep the legacy HDPE closure that they knew worked.

“We didn’t want to have an issue with a closure. And we felt there was enough testing going on with the bottle itself, so we didn’t want to also be working on testing a different cap than the one we knew already worked,” Diez says. “The rigid, injection molded PET neck means we don’t have the leaker issues that so many HDPE bottle and closure systems have.”

Secondary packaging follows in-line, consisting of a Robopac Dimac Nova 30T heat shrink wrap tunnel. Again, the complete lack of corrugated is notable here. Printed, registered shrink film is used to wrap these multipacks, affording them additional branding if they stand alone, stacked from the floor or on an end-of-aisle display in retail, instead of single units residing on the shelf. Clear film is pictured, but Cristalia recently employed decorated, registered film for a better appearance when the bottles are stacked as stand-alone displays

Clear film is pictured, but Cristalia recently employed decorated, registered film for a better appearance when the bottles are stacked as stand-alone displays

“We started with a two by three format for six gallons total in the multipack. We’re probably going to offer a two by two at some point, as well. But our research tells us that two by three is about as much weight as any consumer would be willing to carry, even if they’re stocking up.”

Cases flow to a PAI Palletizer top-down palletizer via AMT conveyor. The pallet pattern works out to seven bottles by seven bottles at each edge, with two, two, and three bottle configurations representing each square face. A square chimney that matches the diameter of one bottle rises up the center of the pallet. Layers are stacked to interlock up to four in height, using only shrink film—no corrugated.

PTI is experimenting with a five-layer high pallet, since the top-load of the BottleOne package can handle the added weight. The blow molder operates with a speed of 5,000 bottle/hour (83 bpm) with each successive piece of equipment rated at a higher speed to assure the products are always being “pulled away” for maximum line efficiency. To determine run lengths and changeover schedule, Cristalia starts with what’s needed to be produced to fill demand, and works backward from there to work out how long lines will be running each SKU or variety.

“Because of the handle, our experience is that you’re not going to get the same output as you would if you bought that same stretch blow molding machine for just a regular preform. I’m sure you could have more cavitations than you do with this integral handle preform, but all that was embedded in our analysis. We knew from the beginning that we were sacrificing a little speed and a little volume for the better bottle design with a handle, and the ability to use rPET,” Diez says of the throughput. “As with any producer, we want to limit changeovers, so we’ll do a few days of each product, store them and then move on when we meet the projected sales volume. What represents most of the volume is the regular Cristalia purified water, so we tend to switch back to that.”

More generally Diez says of the equipment on the integrated line, “We pride ourselves in using top names in packaging equipment manufacturing just because you need to have a constant conversation with them. You need to be able to have 24-hour access to them, and their support. It also gives credibility to the process as well, which is important for everybody involved.” Shrink-wrapped multipacks flow to a palletizer via AMT conveyor.

Shrink-wrapped multipacks flow to a palletizer via AMT conveyor.

Results

Diez’s analogy of Spanish conquistadors burning their ships to symbolize commitment didn’t end at PTI’s shuttering of the legacy HDPE line. It also extended to the retail shelf. Once the new BottleOne PET line was reliably up and running, the team at Diesco worked closely with Walmart stores on the island to arrange for an early morning shelf swap of its legacy HDPE format for its new PET bottles. Instead of consumers being gradually weaned off HDPE jugs of Cristalia over weeks, the brand flipped the packaging format switch in one fell swoop.

“One Monday morning at 5 a.m., before the store was open, we wanted to come in with a team and literally empty all the shelves of our old product, and replace it with the new,” Diez says. “We needed their help logistically on a few things, but Walmart committed to it. When the consumer left Walmart on Sunday, there were all polyethylene bottles. When they came back on Monday, there were all PET bottles. It was quite an interesting process.”

According to Diez, consumer acceptance since the switch was flipped has been “fabulous. Better than we even expected,” he says. “We were able to reduce the price thanks to the efficiency of the line, so consumers are getting a better environmental package, a reduced price, and a better-looking product. And we’ve got the capacity to supply the whole island in hurricane season, so these larger format packages are crucial. When hurricane seasons come and we have emergencies, it really makes all the difference in the world. We felt from a consumer standpoint, that it was going to be a home run—that was obviously in our analysis in our Excel spreadsheets. And I’m happy to report that it has been.” A PAI top-down palletizer anchors the line.

A PAI top-down palletizer anchors the line.

Retailers love the format, too, he says. The likes of Walmart and Costco expected Cristalia’s PET to be a hit among consumers, but they also stood to benefit from supply chain efficiency.

“The difference is astronomical from what it was before today. No leakers and no corrugated, which the retailers had to deal with afterwards. This was a win/win. We have not heard one complaint from the consumer or the retailers, so the Walmarts, Costcos, and Sam’s Clubs of this world are happy with this. And all the local retail chains on the island are happy with the product. We’re now starting to export it to the rest of the Caribbean as we’ve gotten very comfortable with the process. It’s really a transformational product that we’re proud of.”

What’s next

Operational efficiencies continue to improve on the line, though most of the heavy lifting of ramp-up is complete. Cristalia and PTI were conservative with the first pallets that left the line, stacking them to four layers and using slip sheets. Slip sheets have since been deemed unnecessary, and the company is experimenting with a fifth pallet layer.

“This is polishing that needs to happen at an operational level,” Diez says. “How can we reduce packaging even more? How can we be more efficient logistically? Now that we are comfortable with the consumer and retail acceptance of the product, how do we make this even more efficient? How can we take more costs out of it? That’s the next step now.”

Diez also hopes his installation serves as a demonstration platform for other companies looking into BottleOne. Unlike HDPE jugs, the BottleOne PET format’s top-load strength allows for stacking without corrugated. Shown here in four layers, the company is currently experimenting with adding a fifth layer.

Unlike HDPE jugs, the BottleOne PET format’s top-load strength allows for stacking without corrugated. Shown here in four layers, the company is currently experimenting with adding a fifth layer.

“I think the savings are going to be even greater in other industries, like dairy and edible oils, where damaged bottles and leakers present a messier problem than does water,” Diez says. The integral handle comes in handy in foodservice or janitorial environments, too, for applications like cooking oil or disinfectants. The BottleOne format combines the one-handed pour convenience of the HDPE jug-like handle with the supply chain and sustainability perks of PET bottles.”

The next big thing for the Cristalia brand will be adding post-consumer resin (PCR) to the PET stream, for food grade, rPET content bottles.

“We’ve already done testing with postconsumer resin—not in the gallon per se, but in the half liter and the 8-oz bottle. We feel comfortable that the product works, so the biggest challenge is going to be the price point, because PCR is more expensive than virgin resin. What’s next is incorporating that resin, and figuring out the pricing strategy. We expect to be on our way sometime in 2025, with 25% PCR partially inserted into these products.” PW

.cEsxp9NpCv.jpg?crop=focalpoint&fit=crop&fp-x=0.5&fp-y=0.5&h=167&w=250&auto=format%2Ccompress&q=70)