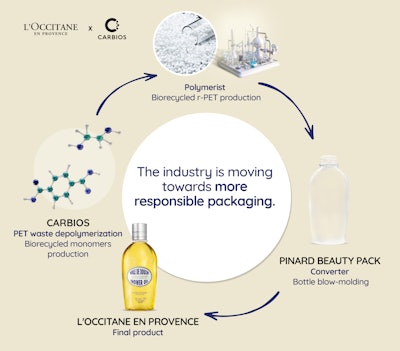

Today at Edition Spéciale by LuxePack, the sustainable packaging show for luxury brands, taking place in Paris this week, international cosmetics brand L’Occitane en Provence and biochemistry company Carbios introduced a transparent PET bottle made entirely from enzymatic recycling for L’Occitane’s Amande shower oil range.

The 100% recycled PET bottle from Carbios’ enzymatic depolymerization process was made entirely through a European value chain. Says Carbios, this European approach optimized the environmental benefits of the technology and the life-cycle analysis (LCA) of the product by reducing transport distances and integrating local collection and production processes.

Carbios’ enzymatic depolymerization process allows for a completely circular system for PET packaging.

Carbios’ enzymatic depolymerization process allows for a completely circular system for PET packaging.

The feedstock for the rPET—comprising colored bottles, multilayer trays, and mechanical recycling residues, none of which are currently being recycled using conventional technologies—was collected, sorted, and prepared locally. The material was then delivered to Carbios’ industrial demonstration plant in Clermont-Ferrand, France, where it deconstructed the PET waste into its original monomers—purified terephthalic acid (PTA) and monoethylene glycol (MEG)—using its biorecycling technology. The resulting monomers were then repolymerized into new, fully recycled PET resins within Europe. In Oyonnax, France, these resins were then blow-molded by Pinard Beauty Pack into bottles meeting L’Occitane’s specifications.

Explains Pinard Plant Director Paolo Coelho, “The bottle was blow-molded under the same conditions and with the same parameters as virgin or mechanically recycled PET, a considerable advantage for the deployment of Carbios’ technology.”

The resulting bottles were then filled by L’Occitane with its shower oil at its plant in Manosque, France.

The environmental benefits of biorecycling

According to Carbios, recent lifecycle analyses calculated with the ecoinvent datatase shows a 57% reduction in CO2 emissions compared to virgin plastic production, and for every metric ton of recycled PET produced, 1.3 metric tons of oil are avoided. Compared with conventional recycling, enzymatic recycling is five times more circular, when calculated according to the Ellen MacArthur Foundation’s Material Circularity Indicator. The Material Circularity Indicator (MCI) is a methodology to measure how restorative the material flows are. The MCI gives a value between 0 and 1, where higher values indicate a higher circularity. Says Carbios, the MCI value for its enzymatic recycling process is 0.8.

To achieve efficient PET degradation, Cabrios uses a highly selective enzyme in its depolymerization technology that can handle virtually all types of PET waste, including colored, multilayer, or textile waste that cannot be recycled with current technologies. Carbios’ technology therefore complements mechanical recycling technologies. Furthermore, the two monomers produced (PTA and MEG) make it possible to recreate recycled PET products suitable for food contact and of identical quality to those of petroleum origin.

Collaboration, local production required

On the back panel of the shower oil bottle, L’Occitane shares with consumers details on the unique rPET packaging, saying (roughly translated from French), “L’Occitane en Provence, Committed to planet change! And collaborates with the French company Carbios, whose unique biorecycling technology allows to recycle a wide variety of plastics. By choosing this bottle of Amande Shower Oil, you can make a more responsible gesture in favor of our precious planet.”

Says David Bayard, R&D packaging director, L’Occitane, “At L’Occitane en Provence, we’re Cultivators of Change, and we’re proud to be part of this forward-looking industry. Today, just over 50% of our PET material is from recycled origin. Thanks in particular to Carbios and depolymerization technologies, we will be able to reach 100% by 2027 for all our retail bottles.

“We are very satisfied with the quality of the bottle produced in collaboration with Carbios and Pinard, which enables us to reduce our reliance on fossil-based plastic and offers a viable alternative with equivalent quality and transparency, which is important to showcase our products.”

| Read about another unique molecular recycling project in this article, “L’Oréal Pioneers Bottle Made from Industrial Emissions” |

According to Carbios CEO Emmanuel Ladent, to meet the needs of the vast number of international brands looking for greater PCR content in their packaging, similar chains will have to be established worldwide, drawing inspiration from this example.

“Carbios’ innovation accelerates the transition to a circular economy by offering an alternative to petro-sourced PET and a circular PET recycling solution that reduces CO2 emissions by 57%,” he says. “But to create an efficient recycling sector, all players in the value chain have their part to play and must work together. The long-term partnership between Carbios and L’Occitane is testament to this shared desire to promote more responsible consumption. The bottle produced with L’Occitane and its converter Pinard illustrates how the industry is moving forward.” PW