Earlier this year, Mars announced that it had adopted simulation software that stakeholders say has the multinational CPG primed to reimagine the packaging innovation process through digital technology.

The maker and packager of household brand names including M&M’s, Royal Canin, and Snickers is leveraging the new simulation approach to perform virtual testing and prototyping on new packaging innovation, initially across its Snacking portfolio. The multi-physics simulation technology from Ansys minimizes the need for extensive physical testing during the packaging development process.

“Modeling and simulation tools have historically been used broadly within the aerospace and automotive industries for years, and now, these cutting-edge tools are beginning to be used for everyday products, including fast-moving consumer goods and packaging. This is especially important as companies, like Mars, are seeking to optimize their sustainability goals and objectives,” says Darren Logan, VP, science research, Mars Science & Technology.

So how does it work? We asked Ansys to give us the quick and dirty version.

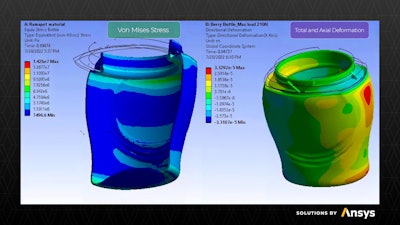

“Ansys uses digital data for model creation to perform analysis. This data can come from scans that would be converted to Finite Element Models [FEM],” says Amit Nair, Ansys' manager application engineering. “Ansys’ engineering simulation technology is used to design products that need to efficiently survive specific operating conditions and loads. To understand how a product will respond to real-world use, [brand] customers [like Mars] use our multi-physics simulations to study the complex ways various physical forces, such as structural stress, fluid dynamics, and electromagnetics, interact. It’s like a virtual sandbox, allowing engineers to play around with their virtual prototype, getting predictive insight into how it will perform under certain operating conditions. That allows them to improve product performance and reliability and often eliminates the process of building a prototype that was doomed from the start due to its design, so it’s a huge saver of time and cost as well. … Our broad portfolio of simulation solutions spans the entire range of physics, allowing our customers to simulate just about anything, from a 5G antenna to the optical performance of systems.” Ansys uses digital data for model creation to perform analysis. This data can come from scans that would be converted to Finite Element Models.

Ansys uses digital data for model creation to perform analysis. This data can come from scans that would be converted to Finite Element Models.

The technology also provides in-depth insights into various aspects of the complex production phases, including wrapping, drop tests, and failure scenarios, the companies say. On an enterprise-wide level, the investment ultimately aims to supercharge efforts to use 100% reusable, recyclable, or compostable packaging for its products.

“Mars initially used Ansys’ tools and engineering software to design our manufacturing and packaging processes and equipment due to our overall complexity," says Logan. “With the understanding that Mars is a global business of people and brands with a clear purpose, we believe the world we want tomorrow starts with how we do business today. It is the vision at the heart of our Sustainable in a Generation Plan - one where the planet is healthy, people and pets are thriving, and society is inclusive. To help us achieve and possibly accelerate our Sustainable in a Generation ambitions, Mars began to apply Ansys’ software engineering tools and simulations to improve its products and packaging for our consumers.”

The implementation of simulation software facilitates a more nimble, digital-first development environment at Mars, spanning from design to manufacturing, making the process easier and more efficient for its team of R&D experts as the company looks to expedite the pace of progress across its packaging ecosystem. Mars is hardly new to the company and technology, but its ability to both optimize for sustainability, and save testing material while doing it, is really coming into its own today.

“Our relationship with Ansys spans over 13 years. Throughout this time, we've successfully leveraged their tools in developing our proprietary wrapping machines, optimizing various processes, and designing innovative packaging solutions,” adds Elias Taye, principal scientist - R&D simulation, Mars Snacking. "In support of our NetZero initiatives, we're exploring the use of sustainable paper for our chocolate bar wrappers. Ansys' optimization tools have enabled us to run design of experiments simulations more efficiently to improve the paper wrapping process.” Mars is beginning to apply and expand these types of Ansys modeling and simulation tools across the other Mars segments, including Mars Food & Nutrition and Mars Petcare.

Mars is beginning to apply and expand these types of Ansys modeling and simulation tools across the other Mars segments, including Mars Food & Nutrition and Mars Petcare.

"“It’s important for us to look at new materials that are not going to be harmful to the environment. Through modeling and simulation, we can accelerate that process. The tools that Ansys brings to bear help us to understand that virtually, before we even bring the materials in house," adds Jim Kennedy, computational science discipline leader at Mars.

Researchers at Mars have already reported reductions in development time of up to 40% through computer modeling and in the quantity of plastic purchased by Mars for testing by approximately 246 tons already by March of 2024.

“Our goal is to significantly minimize the need for physical testing and have more accurate information of max load carrying capacity of our plastic bottle, as well as max fill level of our candies to meet the EU regulation,” Taye says.

The food and pet care provider also says that it is also working to redesign more than 12,000 packaging types across its portfolio to fit with the recycling infrastructure that either exists today or is likely to exist in the future, making it easier for consumers to recycle their packaging.

“Similar to what we are doing with Mars Snacking, Mars is beginning to apply and expand these types of Ansys modeling and simulation tools across the other Mars segments, including Mars Food & Nutrition and Mars Petcare. This approach has allowed us to improve the quality and sustainability of our products and packaging, as well as optimize the efficiency of our product manufacturing,” Logan adds. “In the world we want tomorrow, no packaging becomes waste,” says Qing Qi, VP R&D global innovation, Mars Snacking. “This vision is at the heart of our multi-billion dollar Sustainable in a Generation plan and will only become a reality by taking unconstrained strides, leveraging breakthrough science, innovative thinking and partnerships to push the boundaries of what's possible.”

“We continue to see the impact and potential of simulation and digital engineering in progressing sustainability initiatives throughout the world,” adds Walt Hearn, SVP of worldwide sales and customer excellence at Ansys. “Mars has successfully implemented the pervasive insights of Ansys simulation to optimize its design and packaging processes. Mars’ more sustainable approach to development sets a terrific example for other manufacturers to adopt new solutions that move us all toward a cleaner planet.”

“As for data ownership, in this case, if it’s a Mars model, Mars owns that data exclusively,” adds Nair. PW