Large-enterprise brand owners, major retailers, and their most robust packaging suppliers all rely on sometimes complex stacks of sometimes discordant supply chain management technology, from ERPs to demand planning and vendor management tools. These are often spread unevenly across different regions or functions within a company, and data is rarely compiled the same way between any two platforms. So, it’s tricky to get those disparate systems to speak the same language across a large enterprise in such a way that yields the accurate, actionable information about trade-offs that are needed for sound decision making.

But a growing resource planning platform with a billion-dollar valuation called o9 that seeks to do just that—to integrate disparate data in disparate formats within a single “digital brain.” The company’s state mission is “to provide global companies with a game-changing planning platform to transform their supply chain, commercial, finance, and sustainability decision-making.” The company aims to coordinate supply chain tech stacks in such a way that outputs the best, most accurate, apples-to-apples data in a single dashboard, with the assistance of what it calls AI (Augmented Intelligence). The platform seeks to optimize two pillars for brand owners: decision-making intelligence around P&L, and sustainability reporting (such as ESG metrics).

Here at the Chicago stop on o9's aim10x supply chain digital transformation tour, two themes quickly emerged as major, top-level considerations for brand owners and retailers implementing new enterprise-level, transformative supply chain management platforms and software. Speakers from companies ranging from WestRock to Kraft Heinz, in roles spanning former Walmart supply chain SVPs to current Ralph Lauren business transformation leads, everyone seemed to coalesce on two general themes.

First, these companies say that brands adopting true enterprise-wide supply chain software can't let perfection be the enemy of the good. They advised taking small wins where you can, and building off them, instead of trying to turn the whole aircraft carrier all at once. Compartmentalize business units and tackle pieces in digestible chunks, they said. After all, harmonizing data across an enterprise, where packaging is just one of a dozen elements, is difficult work. (from left) Mike Brodsky, Supply Chain Transformation Leader, WestRock; Brian Houck Supply Chain Consulting Practice Leader, PwC.

(from left) Mike Brodsky, Supply Chain Transformation Leader, WestRock; Brian Houck Supply Chain Consulting Practice Leader, PwC.

“You will never have systems, people, and processes ready all at the same time: you need to take a modular approach,” said Jason Malyil from Ralph Lauren.

Also, they all emphasized extending a large does of empathy to the end user—always a human or team of humans—who will be using any platform or software. When implementing a new system on this scale, keep that end user not only in mind, but at the center of the decision-making and onboarding processes. In some cases, an employee may equate their entire value proposition within the company with the Excel sheets he or she had carefully maintained for years. People can feel territorial and defensive at what they might consider the prospect of becoming obsolete. Empathize with their experience and find ways to take them with you in the organization. And prepare them to win with training and support. If thrown to the wolves of a new platform, and left to their own devices, recidivism to legacy (often offline) platforms like Excel is common.

But also, keep in the back of your mind that that data belongs to the company. Its highest and best purpose is in informing decisions and clarifying trade-offs for the whole enterprise. That’s why it’s important to get those individuals onboard with wider, common company goals, rather than narrower department-level KPIs.

In what I’d call the quote of the conference, Malyil distilled this principal. "The difference between implementation and transformation is adoption,” he said.

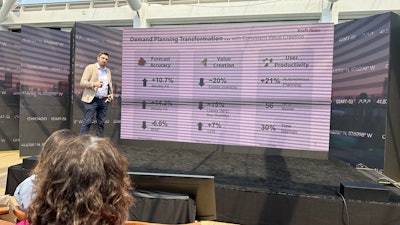

Kraft Heinz’s KH Hive and O9 Use Case

AI-powered demand planning & forecasting, which impacts packaging machinery and material acquisition strategies among a host of other procurement decisions, is an ongoing project for o9 customer Kraft Heinz its KH Hive platform. But early returns are more than promising according to Adis Sulejmanović, yesterday at the aim10x o9 tour stop in Chicago.

Four early takeaways on how brands should approach digital transformation of this sort:

1. View data as an asset that must be maintained, nurtured, . "Garbage in, garbage out" is a fact of data management.

2. Before you apply AI-based forecasting, know how your processes currently works, and what problem you're trying to solve with new platform. Adis Sulejmanovic, Head of Digital Supply Chain Transformation and Strategy, Kraft Heinz

Adis Sulejmanovic, Head of Digital Supply Chain Transformation and Strategy, Kraft Heinz

3. Collaboration is key. Kraft Heinz was an early adopter brand in this space, and still found platforms from which to build. You don't have to reinvent the wheel.

4. Echoing what others have said, don't let perfection be the enemy of the good. Be prepared to fail but do so quickly and move on (fail fast). A leadership structure that understands that wrong turns are expected, correctable table stakes in this space is essential.

“When you think about digital transformation, what is most important is the beginning: it’s important to start the journey and take the leap,” Sulejmanovic concluded. PW

![Frain2020 41[1]](https://img.packworld.com/files/base/pmmi/all/image/2024/06/Frain2020_41_1_.666a0c6a1ffa0.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)