This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

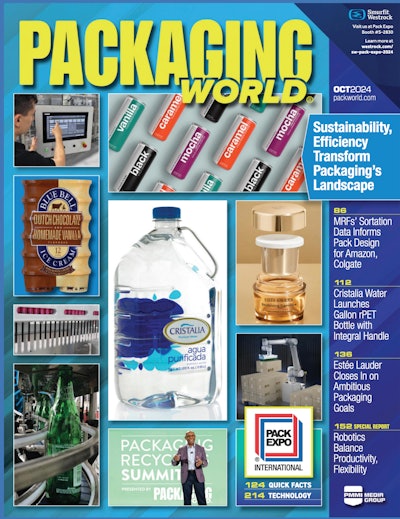

BW Flexible Systems, a global expert in flexible packaging solutions, will launch its re- engineered Thiele UltraStar G2 Bag Filler at PACK EXPO International 2024 in Booth S-2100, held November 3 to 6 in Chicago.

This second-generation machine is the latest addition to the Thiele Star series, a series of bag filling solutions known for its strong reputation in the pet food, animal feed, sugar, milling and fertilizer industries. It builds on the success of the original UltraStar by enhancing reliability, streamlining maintenance and improving durability to boost overall equipment effectiveness and optimize return on investment.

“The UltraStar G2 Bag Filler represents our commitment to innovation driven by customer needs,” said Jan-Pieter Grootendorst, Global Product Line Leader for Palletizing at BW Flexible Systems. “Our goal is to deliver a machine that ensures seamless operations and supports long-term performance.”

After gathering extensive customer feedback and in-depth analysis, BW Flexible Systems made several key upgrades to the UltraStar G2. The re-engineered design minimizes unplanned production stops, reducing downtime and increasing reliability.

“Manufacturers today face growing pressure to improve efficiency while controlling costs,” said Braden Beam, Global Product Line Leader for Bag Filling at BW Flexible Systems. “With the UltraStar G2, we provide a solution that meets these challenges by offering easier maintenance and long-term durability to evolve with shifting market needs.”

Additionally, BW Flexible Systems simplified the design of the UltraStar G2 to lower overall maintenance costs. The machine now requires fewer spare parts and increases maintenance accessibility, simplifying repairs. This streamlined design enables quicker parts replacement and a smaller inventory of spare parts on hand to save on maintenance costs.

“We’ve engineered the UltraStar G2 for easy maintenance, so teams can make adjustments quickly and keep production lines moving,” said Beam. “We focused on making the machine more user-friendly and cost-effective in the long run.”

On top of a simplified design, the UltraStar G2 Bag Filler integrates seamlessly with Symach palletizing solutions to optimize entire packaging lines. See the Thiele UltraStar G2 in action and learn more about Symach palletizers in booth S-2100 at PACK EXPO International. Learn more about the Thiele UltraStar G2 Bag Filler.

BW Flexible Systems is one of three divisions—alongside BW Filling & Closing and BW Integrated Systems—which together comprise BW Packaging, Barry-Wehmiller's packaging machinery group. With a global footprint spanning 25 countries, BW Packaging is distinguished by its commitment to the performance of its products, integration services, sustainable offerings and lifetime support for every solution.