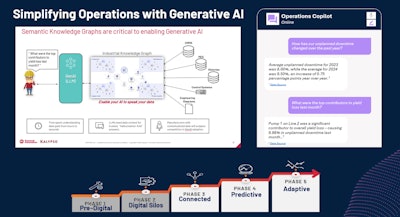

Rockwell has expanded its FactoryTalk Design Studio software-as-a-service design software with a new generative AI Copilot, developed in partnership with Microsoft. The latest feature, powered by Microsoft Azure OpenAI Service, enables controls engineers to use natural language prompts for tasks like product guidance, code and ladder logic generation, code and ladder logic explanations, and troubleshooting, making system-design faster and more intuitive. Accessible through a web browser without downloads or installations, FactoryTalk Design Studio with AI Copilot provides a collaborative, multi-user environment with integrated version control and is continuously updated with new capabilities to enhance productivity and efficiency in industrial automation system design.

“Think about the proliferation of large language AI models like ChatGPT and the like. What if CPGs can now make use of natural language prompts to accelerate the process of building ladder logic as a controls engineer? That’s what Design Studio Copilot is trying to achieve,” said Chris Barnes at PACK EXPO International, just before Automation Fair. “Think about the workforce issues companies face, and think about new people having to rapidly come up to speed with what the code base is all about. And then think about them writing the code and optimizing a code base. It’s really a step change in the way controls engineers can do their day-to-day tasks.”

An engineer can directly ask the AI Copilot, ‘Can you develop a pattern, and write ladder logic for me, and input certain parameters around a given process, like filling or cartoning or case packing. The operator can then work with the AI to continue to interact, refine, and add smart objects to get to a specified packaging process.

“The way you set up a Design Studio project is you have a Smart Object that is a container of programs or routines. You have a program underneath it, and then you have a routine where the code actually lives,” said Tony Carrara, business manager at Rockwell during an Automation Fair demo of the tech. “We do that to drive reusability of content. I can build a Smart Object—a container of code—and then I can use it again and again in different places. Copilot lets me use a natural language prompt to create that structure. For instance, if I want to create a Smart Object for a temperature control routine on a process, I can simply tell the Copilot, ‘Create temperature control to monitor temperature across five tanks.’ … The technology that Design Studio was built on allows us to have that integrated chat panel so a controls engineer is not switching off to another app, they’re not searching the internet, they can really stay in the flow their work. And another paradigm with Design Studio is that after you write the code, you can allocate it to a controller. I can build my system out and model it, and then I can pick my execution surfaces (PLCs) that I want to deploy it to. In this case, I can use the AI chat panel to say, ‘Allocate the new code that I just made to a certain control Logix.’ Just using that natural language prompt, the code will be added to the default task of the desired controller.”

Small Language Model AI at the Edge

Rockwell’s Microsoft collaboration will also introduce Rockwell’s FactoryTalk Optix Food & Beverage model, enabled through Rockwell’s digital and service offerings, into the Microsoft AI model catalog. The model brings generative AI directly to the edge of an automated packaging line that uses it. The adapted AI model, using Microsoft’s Phi-3 small language models (SLM), will provide packaging machine operators with AI-guided instructions, assisting in process and device operations via the familiar FactoryTalk Optix interface. With specifically trained models, operators at the edge can access contextualized AI guidance to enhance productivity, reduce errors, and accelerate decision-making.

.OvcZHe3G0k.jpg?crop=focalpoint&fit=crop&fp-x=0.5&fp-y=0.5&h=67&w=100&auto=format%2Ccompress&q=70)

.cEsxp9NpCv.jpg?crop=focalpoint&fit=crop&fp-x=0.5&fp-y=0.5&h=167&w=250&auto=format%2Ccompress&q=70)