It’s no secret that CPGs are suffering from a workforce problem. Flip to page 100 for more from our Annual Outlook Report, but the short version is about 80% of Packaging World readers are having trouble finding and retaining packaging line labor. It’s hard to find operators and technicians, and costs associated with training them becomes burdensome with high turnover that is increasingly common in the industry.

Can AI help? AI Special Report, ChatGPT burst upon the scene two years ago, seemingly overnight, taking all of us by surprise. In truth, literally decades of efforts in AI predated the breakthrough.

But now that we’ve all had a chance to experience generative AI in the form of a chatbot, flaws and all, it’s not hard to see where this is headed. Packaging World's recent coverage on the topic from Rockwell Automation Fair and PACK EXPO International indicates that some of what’s possible is no longer nascent; it’s already being implemented in select cases. But what if all operators and technicians could chat with their machines directly?

Whether that means getting the right answers for a changeover procedure or trouble-shooting a root cause of downtime, a natural-language interaction with the equipment could be more intuitive than operating an HMI. That could reduce the burden of skill required to operate and maintain the machine using today’s HMIs. And that’s where AI could become a useful answer for the workforce issues that CPGs and food processors are experiencing.

At a PMMI event last year, Danone’s Director of Innovation & Packaging Engineering Shawn French asked the audience, “Do you remember your iPhone training?” It was a tongue-in-cheek reference to the fact that the groundbreaking user interface, which today we all take for granted, was so intuitive at the time that no training was needed to operate what is essentially a highly sophisticated, pocket-size computer with a novel interface.

It’s true that packaging machines are not cell phones; with technical data, warnings, or parameters that are difficult to simplify, along with diverse, complex operational states, safety considerations, and even regulatory constraints, HMIs are necessarily more complex than a phone and require skill to operate. Nor are we suggesting that HMIs will go away.

But what if AI-powered chat were built into every machine? Could that help simplify operation and address the worker quality and quantity problem?

We put the question to readers like you, who work at CPGs. The survey was conducted via email to Packaging World’s CPG and brand owner audience in December 2024 and reflects the views of 95 total respondents.

As the charts show, most respondents indicated a high degree of interest in integrating AI chat into packaging and processing equipment (see top chart, page 70). As one respondent wrote, “Anything that creates a venue for maintenance or operators to get quick ‘how-to’ answers is a no-brainer.”

Another wrote, “Using an AI chat that was fully capable of accessing the equipment manuals and repair/setup aspects could be much easier and faster than searching either on paper on even electronically.”

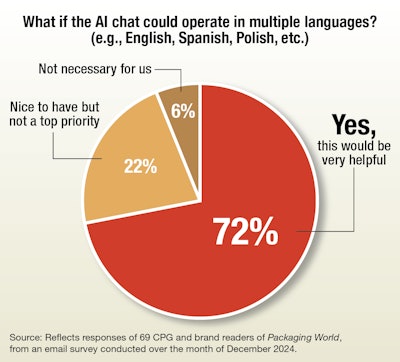

Others have started to use AI elsewhere and concur on the potential: “We are finding AI helpful in so many areas now. Writing job postings, communicating with employees in different languages. It would be helpful to get immediate answers to the issues we face during production.”

Another wrote, “It could help the next generation of operators to understand and troubleshoot the equipment.”

However, there were skeptics.

“Details, details, details,” one respondent cautioned. “Need to understand the scope of the tool and interaction(s) with HMI on the shop floor. Would need to understand how the AI tool interfaces with non-OEM plant or company specific process(es) to avoid conflicting instructions.”

Another said, “Our industry would function more safely with well-defined logic. AI at this point isn’t transparent enough in its decision making.”

A third respondent suggested that AI chat doesn’t go nearly far enough. “AI interactions will not be helpful. What will be helpful is when AI can make decisions during a run without interacting with operators. For example, if print registration starts to slip, AI makes micro-adjustments to maintain registration on its own, no operator involvement. Having the equipment interacting with the operators will cause more headaches than it’s worth.”

The reality is that this kind of truly autonomous operation remains years in the future for a host of reasons related to safety, regulatory, liability, and technology-readiness issues. Also, it’s engineering of a different magnitude from the OEM’s perspective: true autonomy requires changes in control logic, sensor data, and the addition of robust machine learning models that go well beyond what a chatbot interface requires. The AI chat described in this survey is an operator and technician support tool and communication channel, not dynamic or autonomous machine operation.

Recognizing that no technology is perfect, another countered not to let the perfect get in the way of the good. “Instant response is better than no response or searching for a manager.”

And another said, “More intuitive HMIs would be higher on my priority list.” Another dismissed any issues with HMIs, saying “Operators generally learn how to operate the equipment and become familiar with the machine setting screen info.”

Not just chat

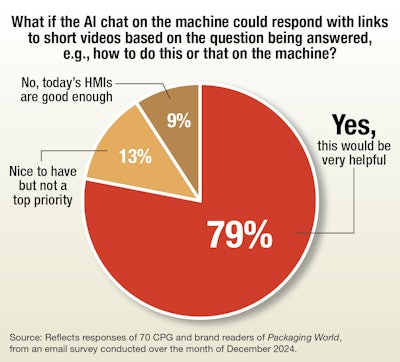

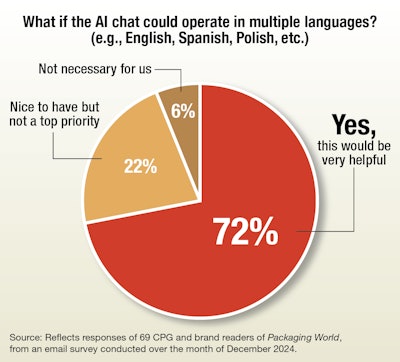

The survey was designed to expose different potential features and capabilities to CPG professionals involved in buying and supporting equipment, including the ability for AI to:

• Respond to operators in a chat with links to short videos

• Operate in multiple languages

• Offer “push-to-talk” functionality bypassing the need to type

A majority of respondents said these features would be “very helpful” on their packaging and processing equipment. “Shortcuts to helpful videos, speaking to equipment on info needs/changes instead of just typing info in would be very helpful additions related to AI capabilities,” wrote one respondent.

Of course, plants can be loud, and factory-specific tuning of the audio or special microphones may be required for push-to-talk functionality.

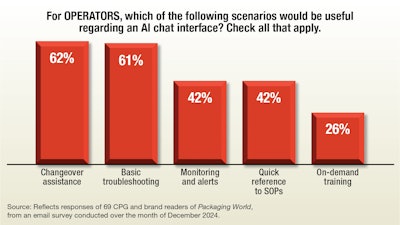

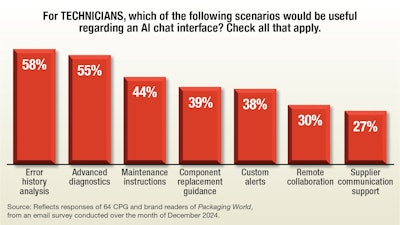

The survey then went on to ask respondents to score a handful of use cases for both operators and technicians. See charts above and below, and reference the sidebar below this article (scroll down for detailed definitions and examples used in the survey.

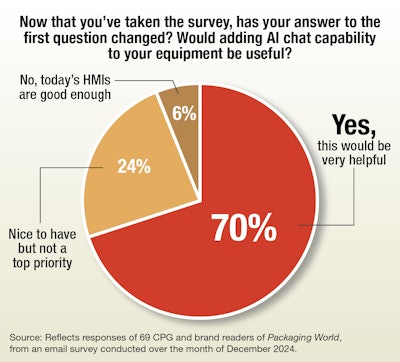

The survey was also a bit of a trojan horse, designed to educate respondents about all the possibilities. That’s why we tacked on a question at the end, asking respondents whether their initial answer (about whether AI chat embedded into equipment would be useful) has changed once they went through the survey and saw all the potential use cases. Those answering “very useful” jumped from 59% to 70%.

Finally, we asked whether AI chat functionality would be more useful in packaging equipment or processing equipment. The clear majority said it’s equally useful in both, though there were a fair number that leaned more toward wanting to see it on packaging equipment.

The tools available to both OEMs and CPGs for incorporating AI are rapidly evolving. Several of the large automation suppliers including Rockwell Automation, Siemens, Schneider Electric, Beckhoff, and B&R have released “copilot” style functionality for writing PLC code, and some are already experimenting with AI chat style functionality. There are also several third-party tools available today that bear exploring. It’s early days still, but the appetite does appear to be there for exploring how AI and AI chat could support the operation of packaging and processing equipment while reducing the potential burden around training and support, leading to more uptime.

While a natural language interface can reduce friction, it should be clear that operators and technicians will still need fundamental training to interpret machine feedback safely and efficiently. At the end of the day, packaging equipment is mission-critical, and AI chat is not a substitute for thorough instruction and understanding of how equipment operates. A poorly trained operator can make mistakes even with top-notch AI chat. Nor, as indicated earlier, is AI chat a replacement for the HMI. Sometimes it’s just faster to press a button.

But incorporating some sort of AI chat seems sensible and, perhaps, inevitable. The first step would be a pilot project with a cooperative OEM and newer/less-experienced operators who might benefit the most.

.OvcZHe3G0k.jpg?crop=focalpoint&fit=crop&fp-x=0.5&fp-y=0.5&h=67&w=100&auto=format%2Ccompress&q=70)

%20REV2.wabPeUjAvt.jpg?crop=focalpoint&fit=crop&fp-x=0.5&fp-y=0.5&h=167&w=250&auto=format%2Ccompress&q=70)