I’ve enjoyed learning about, reporting and commenting on packaging advances for 60 years—the last 30 as a contributing editor to Packaging World.

As I approach retirement in 2024, I’ve been thinking about the fantastic advances packaging has undergone in the past six decades, and the people—my wife, family, friends, associates, competitors and coworkers—who’ve challenged and encouraged me to strive to become a “fit for purpose” packaging journalist. “Fit for purpose” is an English phrase defined by the Cambridge Dictionary as “something that does what it was meant to do.”

The following observations reveal that the seeds of my curiosity about and interest in packaging were sewn long before I first was amazed at how a vf/f/s machine could automatically transform a fat roll of film into a slim stream of filled pouches at an amazing 60 ppm. That was 1963. I'm still impressed with the increasing speeds, ingenious workings, and expanding array of packaging and package-related converting equipment that underpins the packaging community today.

The good people of the packaging community taught me to appreciate packaging as a necessary and noble undertaking: protecting and delivering nourishing foods, health-sustaining treatments and needed commodities to consumers around the world. As the British might say, packaging is “fit for purpose.”

The Institute of Packaging Professionals’ packaging glossary defines both “package” and “packaging” as “a form that is intended to contain: protect/preserve; aid in safe, efficient transport and distribution; and finally, to inform and motivate a purchase decision on the part of the consumer.” That’s an accurate, if incomplete, definition of packaging. It leaves out all the true wonders of packaging—the mechanical, electronic, robotic, digital, and whatever-comes-next technologies we rely on to convert raw materials and components into millions of identical or, if needed, variable packages while continuously auditing, analyzing and adjusting their own performances with minimal, or, in some cases, no human interface.

These musings on packaging are merely personal observations drawn from an early and accidental exposure to a narrow range of packaging formats that instilled in me an interest in and respect for packaging’s ability to stimulate creativity even as it continues to evolve in its fundamental “fit for purpose” roles.

Musing #1: Value-added recycling—In 1947, Tokyo’s Ginza, now a glittering upscale shopping district, was a rude line of bamboo and canvass lean-tos where toy cars made from recycled beer and soft drink cans were sold for pennies. Recently collectors have been paying hundreds of dollars for those made-from-recycled-can vehicles—a testament to recycling’s ability to reclaim and increase the value of PCR containers and packaging materials, no matter how desperate the prospects may seem. The seven-year-old me and my friends played with the toy cars, crashing them to see what kind of drink logos were hidden in the wrecks. The takeaway here is that recycling, whether mechanical or chemical, can continue to add value and utility to previously used packages and packaging materials, if considered creatively.

Musing #2: Communicating through color—Package color coding today offers a quick hint of the food flavor contained. In the 1940s, crinkly glassine-wrapped Nabisco graham crackers came in a green box, “midori no hako” in Japanese. I’ve forgotten most of my Japanese, but, curiously, that simple packaging descriptor has stuck with me. Today in the U.S. a green package of baked goods says the goods are garlic flavored, so graham crackers are not likely to be clad in midori no hako. But if and when pumpkin-colored graham cracker packages are introduced, it’s a good bet those packages will hold squash-flavored goods.

Musing #3: Dispensing increases pouch appeal—The icebox in our Tokyo apartment held a white, clay-like blob of oleomargarine packed with a drop of yellow food coloring in a clear Pliofilm rubber hydrochloride pouch. The squeezable film pouch was regulated into existence by a dairy industry-supported ban on the sale of yellow margarine that might have been mistaken for butter. Kneading the pouched blob, which we kids saw as play, released the encapsulated yellow coloring, magically turning the white blob into a buttery yellow. While pouched white margarine didn’t last in the market for very long, the pouch’s playful functionality inspired other foods (sour cream, avocado, and peanut butter come to mind) adopted the packaging format and became top sellers in their categories, proving that turning the sometimes-frustrating pack opening process into a winning fit for purpose strategy.

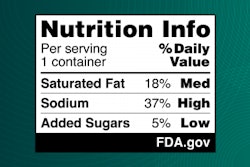

Musing #4: Reality check: Some packs are NOT fit for purpose—An eye dropper package that is NOT fit for purpose, if its purpose is to enable patients to self-medicate, is an elder-unfriendly 2.5-mL polypropylene dropper bottle 1 in. high and 0.5 in. in diameter with a threaded PP cap secured to the bottle with a thick PVC tamper-resistant band that can be removed with the help of a pair of sharp cuticle scissors. The cap is seated so firmly on the bottle it can only be unscrewed with two pairs of pliers torquing in opposite directions. A plastic belly-band label with type too small to read without a magnifying glass, sticks to the bottle. A self-medicating 84-year-old hyperopic patient who has recently undergone cataract surgery, has arthritic hands and a moderate case of age-related macular degeneration—the presumed target customer for this tiny dropper—would be challenged, at best, to properly apply the droplets of medication contained.

The design of this dropper bottle is not unique in its category. But surely the pharma packaging community, with some of the most brilliant problem solvers in packaging, will be able to address its deficits. Addressing the challenges of unfit-for-purpose packaging must be a top priority for all packaging developers. We’re confident that the current generation of pharma industry developers will solve the problem of packages that are unfit for purpose.

Just as surely, the next generation of vocal packaging performance auditors—critics and supporters alike—will be watching. So will I.

Ben Miyares, Packaging Sherpa, is a packaging market and technology analyst and is president of The Packaging Management Institute, Inc.

He can be reached at [email protected].

%20REV2.wabPeUjAvt.jpg?crop=focalpoint&fit=crop&fp-x=0.5&fp-y=0.5&h=167&w=250&auto=format%2Ccompress&q=70)